In industrial and mechanical contexts, "CR bearing" can refer to several different types of bearings. The most common interpretation is a cylindrical roller bearing. Other meanings include combined roller bearings and connecting rod bearings, typically used in engines.

Cylindrical roller bearings

Cylindrical roller bearings (CRBs) are designed to handle heavy radial loads and high speeds. They have rollers that are cylindrical in shape, which provides a larger contact area with the raceways compared to ball bearings.

- Construction: The inner and outer rings are separable, which makes installation and disassembly easier.

- Load capacity: These bearings have a high radial load capacity but are not ideal for heavy axial (thrust) loads, unless they are designed with special flanges.

- Applications:

- Industrial gearboxes

- Electric motors

- Wind turbines

- Pumps and compressors

- Rolling mills

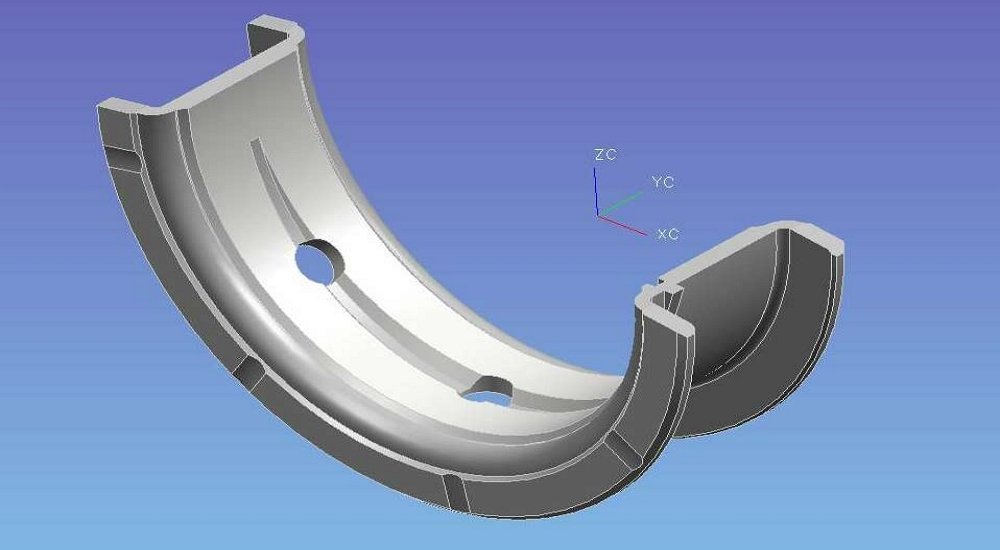

Connecting rod bearings

Connecting rod (CR) bearings are a type of plain bearing used in internal combustion engines to connect the connecting rod to the crankshaft. They are subject to high loads and temperatures.

- Materials: Typically made from a multi-layer composition of metals like copper, lead, and bronze.

- Types: Come in different sizes, including standard and undersize, to accommodate different engine wear conditions.

- Applications:

- Automobile engines

- Marine engines

- Industrial compressors